Twitter Feed

SourceConnecte! Marketplace With A Mission

Earlier this year, GC GlobalNet launched a new breed of B2B e-commerce sites. Curated by Kevin L. Jackson, SourceConnecte (with an “eâ€) went live with three strategic goals in mind: Efficiently leverage modern…

Potential vs. Reality: Is Edge Computing Real?

Edge computing provides compute, storage, and networking resources close to devices generating traffic. Its benefits are based on an ability to provide new services capable of meeting stringent operational requirements…

Enabling Digital Transformation

Digital transformation integrates technology into all areas of an organization’s business or mission. Its fundamental purpose is to create and deliver innovative and industry-changing products and services to a global…

The ThinkShield Story Part 1: The Challenge

The cybersecurity challenge seems to be growing daily. Threats are becoming more sophisticated, and attacks are becoming more destructive while the corporate world’s response seems to resemble a deer…

CIO dream team: Who’s in and why?

Today’s CIO navigates the twin challenges of enabling new business models and managing rapid technological change. Cloud computing strategies are now table stakes. CIOs must make complex decisions about using…

Digital Transformation and the Mainframe

Digital transformation infuses digital technology into all areas of an organization’s business or mission. Its fundamental purpose is to create and deliver innovative and industry-changing digital products and services to…

Composable Architecture Q&A. Are you ready?

Q: Is it time for my company to jump on the composable architecture bandwagon? A: Composable architectures are quickly becoming essential to the modern enterprise. Citing a recent Forrester study:…

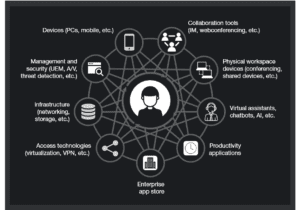

Increase Productivity by Reducing Technology Distraction: Lessons from Forrester Research

Workplace productivity is hurt every day by the very technology developed and purchased to improve it. Forrester announced this surprising conclusion in their latest “How To Wake Up From The Nightmare…

Unveiling the end-to-end capabilities for the networked society

An Interview with Henrik Basilier By Kevin L. Jackson The telecom industry is rapidly moving towards a future in which networks must have the capabilities of delivering services with the…

AT&T Finance Solutions GM on Shrimping, Software, and CX

Helping clients address the trends and challenges presented by the Financial Services industry is the main focus for René Dufrene in his role as General Manager of Finance Solutions at…

|

|

Figure 1– The smart manufacturing landscape https://www.industryweek.com/systems-integration/journey-smart-manufacturing-revolutio

|

( Thank you. If you enjoyed this article, get free updates by email or RSS – © Copyright Kevin L. Jackson 2016)

Cloud Computing

- CPUcoin Expands CPU/GPU Power Sharing with Cudo Ventures Enterprise Network Partnership

- CPUcoin Expands CPU/GPU Power Sharing with Cudo Ventures Enterprise Network Partnership

- Route1 Announces Q2 2019 Financial Results

- CPUcoin Expands CPU/GPU Power Sharing with Cudo Ventures Enterprise Network Partnership

- ChannelAdvisor to Present at the D.A. Davidson 18th Annual Technology Conference

Cybersecurity

- Route1 Announces Q2 2019 Financial Results

- FIRST US BANCSHARES, INC. DECLARES CASH DIVIDEND

- Business Continuity Management Planning Solution Market is Expected to Grow ~ US$ 1.6 Bn by the end of 2029 - PMR

- Atos delivers Quantum-Learning-as-a-Service to Xofia to enable artificial intelligence solutions

- New Ares IoT Botnet discovered on Android OS based Set-Top Boxes